Subsea installation monitoring for world – first Northern Lights carbon capture

Overview

Ashtead Technology delivered tailored solutions to assist with the world’s first-ever carbon capture storage project in the North Sea.

Solution

As the energy transition to net zero carbon output is now underway, Ashtead Technology’s Survey & Robotics teams are perfectly-placed to add value during the construction, installation and maintenance of offshore assets.

Ashtead Technology carried out subsea installation monitoring work to support the Northern Lights Carbon Capture Storage project (CCS) in the North Sea.

Developed by Equinor in partnership with Shell and Total, the Northern Lights project is the first of its kind in the region. The project aims to securely collect and transmit CO₂ from onshore sources and store this under the seabed.

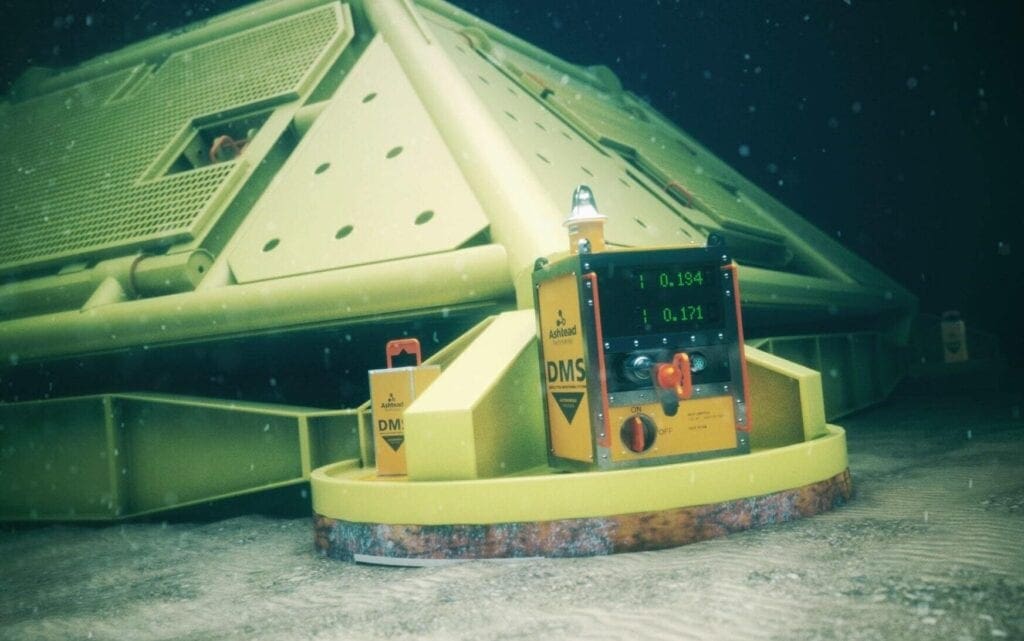

This project marks the first occasion Ashtead Technology has been involved in a CCS programme; providing a leading subsea services company with its integrated Deflection Monitoring System (DMS) and associated equipment. The DMS is a suite of structural monitoring systems to assist offshore construction operations, combining powerful software with modular technology.

Ashtead Technology’s dual independent DMS systems monitored and analysed parameters such as structure deflection, heading, pitch, roll and suction can differential pressures in real-time. This method of real-time monitoring is vital during the placement of suction can-based subsea structures as it ensures any potential issues can be acted upon immediately, reducing the risk of structural damage.

Benefits and value

Using the DMS, Ashtead Technology personnel and equipment successfully monitored the installation of an Integrated Satellite Structure (ISS). During the placement of the structure, the DMS system was configured for autonomous independent operations, communicating data to one of the installation ROVs. Advanced positioning tools and measuring sensors enhanced the accuracy of the data collected, ensuring the reliability of the data.

Testimonial

“The data management requirements of offshore operations are continually changing, with the reliable and rapid transmission of data often meaning the difference between success and failure.”

“We were delighted to have been brought onboard with this project, with our mesh networks for inspection data sharing having a tangible impact on improved operational processes throughout the project.”

Ross MacLeod

Technical Director