Coating Removal, 3D Imaging, Analysis and Precision Cutting for a Pipeline Repair Project

Challenge

Ashtead Technology was contacted by a customer who needed to replace a damaged segment of a 16″ pipeline located offshore in Saudi Arabian waters.

The damaged pipeline segment was to be replaced with a new segment using mechanical connectors.

Before cutting could proceed, the customer required verification that the intended cut locations met nominal pipeline ovality tolerances. This was to ensure the mechanical connectors would fit.

Solution

Ashtead Technology began by deploying our Coating Removal Tool (CRT) to remove the concrete weight coating and fusion-bonded epoxy coating from the pipeline.

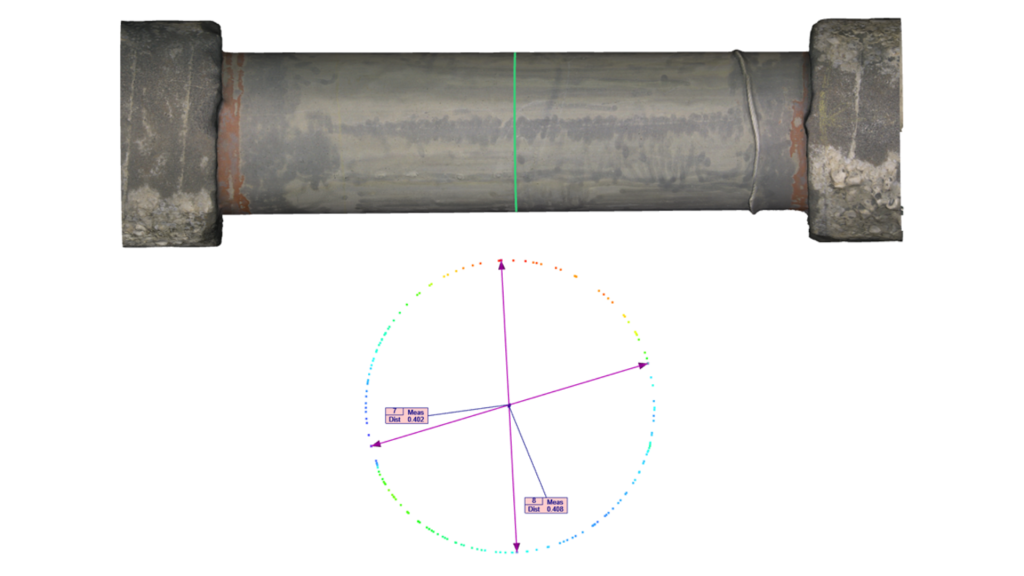

With the coating removed, we deployed the Voyis Discovery Stereo Camera system to perform high-precision 3D modelling photogrammetry of the pipeline segment.

The Voyis Discovery Stereo Camera System, the world’s most advanced photogrammetry tool, captured high-quality 8MP images for post-processing photogrammetry and utilised VSLAM technology to perform live modelling and full coverage data acquisition.

Data collection and 3D model data processing was completed offshore by our expert photogrammetry technicians. This allowed us to inform the customer that the pipeline ovality at the intended cut locations was within manufacturing tolerances and suitable for mechanical connectors.

With the tolerances confirmed, the Ashtead Technology 22” Diamond Wire Saw was used to execute the precise cuts.

Results and impact

Using Ashtead Technology’s Coating Removal Tool, a 1.5m section of concrete weight coat and epoxy coating was removed within twelve hours, delivering a significant time saving for vessel operations compared to conventional methods.

High-precision 3D photogrammetry allowed our technicians to provide the verification requirements with millimetre-level accuracy. This gave the customer confidence that the cut pipeline ends would be suitable for mechanical connectors and the replacement operation could proceed successfully as planned.

By combining Ashtead Technology’s mechanical solutions and asset integrity expertise, we provided our customer with an integrated service package to prepare the pipeline for repair. By managing all aspects of the operation, our customer simplified their supply chain, accelerated mobilisation and improved operational efficiency by reducing the need for multiple offshore team interfaces.

To find out more, contact us today!