Precision cutting for offshore jacket removal

Challenge

Ashtead Technology was contacted by a tier one vessel contractor to support a jacket removal decommissioning project in western Indian waters.

Following cessation of production, we were engaged to deliver cutting solutions for five offshore platform jackets. This involved the swift preparation, testing and deployment of equipment to meet tight project deadlines. The team also had to account for challenging environmental conditions due to the jackets’ location.

Solution

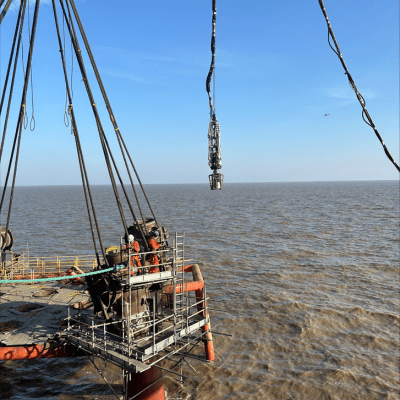

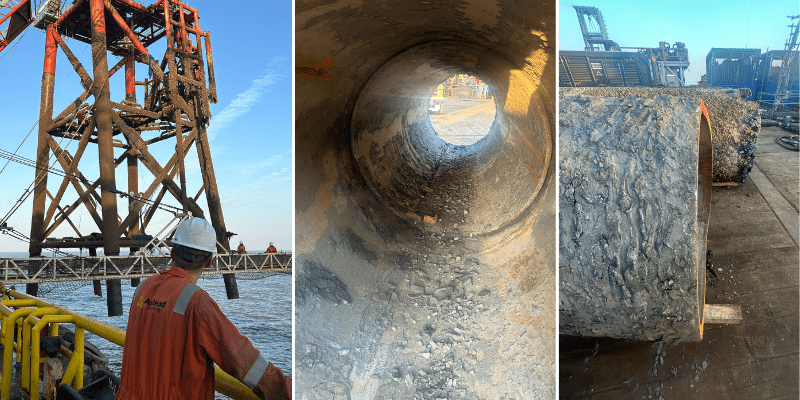

Our skilled experts developed a tailored solution, deploying specialised equipment, including the Ashtead Technology 2500 Bar UHP cutting system with cut verification and an internal pile cutter for precise 360-degree severance. A custom-designed internal soil plug removal airlift system was utilised, along with dedicated auxiliary equipment, rigging and a hose management system to facilitate efficient soil removal. A team of six expert technicians were mobilised from our mechanical solutions team to oversee equipment operation and maintenance.

Additionally, an Ashtead Technology Project Manager was allocated to the client to streamline project delivery, ensuring efficient implementation.

Results and impact

The project was completed safely and successfully, meeting all milestones. All 20 jacket legs (54″ OD x 50mm W.T) were dredged and severed on the first attempt, with an average cut time of under one hour. The five platform jackets were lifted and removed within 60 days, with each lift proceeding immediately after dredging and cutting.

This well-coordinated execution was delivered with precision and efficiency, with a strong commitment to safety, ensuring a successful project with zero incidents throughout.

To learn more about our subsea cutting, dredging, recovery tools or offshore support contact our Mechanical Solutions team.