Dave Oberczyk joined ACE Winches almost 14 years ago as a welding fabricator and since then, his career has rapidly developed. As Head of Sales for ACE Winches, he shares more about being part of the Ashtead Technology group and what life is like in this fast moving and challenging industry.

It has been nine months since the acquisition. What can you tell us of the journey so far?

It’s hard to believe it’s been nine months, but it’s clear that this acquisition has already opened some fantastic opportunities for us.

One of the highlights has been the collaboration that has developed almost immediately. We’ve brought together some brilliant minds from across the group, and we’ve launched a couple of projects that are already showing great promise. Watch out for some exciting news about collaboration between ACE Winches and our survey team in the next few months.

From project design to delivery, our customers now have access to a much wider range of products and services across the Ashtead Technology subsea and back deck technology offering.

What opportunities do you see for growth and development as part of the Ashtead Technology group?

Our core business at ACE Winches of equipment rental for lifting, pulling, and deployment remains the same and we are continuing to develop and add new equipment to our offering.

As part of the Ashtead Technology group, we now have twelve strategically placed hubs in the UK, USA, Norway, Middle East, and Singapore, which means we are connecting with a broader audience, and we are better placed to provide local support to our customers internationally.

You have been with ACE Winches almost 14 years. Tell us about your career journey so far?

I started my career with ACE Winches back in 2010 as a welding fabricator which means I know exactly how our equipment works, and what bit of kit or package of equipment is needed to do a particular job.

I then trained as a Mobilisation Technician before progressing to a Mobilisation Controller role, overseeing the testing, spooling, preparation and mobilisation of all our rental equipment.

Going offshore to our clients’ sites to install and commission our equipment, gave me first-hand experience of what our clients require from us. At ACE Winches the maintenance of our equipment, which is used in some of the harshest conditions is very important. We ensure every piece of equipment is kept to the same quality standard as the day it was manufactured.

It was 2015 where my sales journey began, and I was given the opportunity to become a Sales Engineer. It was a relatively smooth transition from the workshop to the office, as my hands-on experience with our equipment allowed me to not only recommend and provide the right solution to our customers, but also offer solid technical and practical operational advice as well.

Initially, I focused on the UK rental market, but as my experience and knowledge grew, I started covering international markets. Just in the last few weeks we’ve had equipment mobilising to South America and to Gulf of Mexico, as well as Australia so this really is an international operation. This progression led me to roles as Sales Manager and now Head of Sales, which has been a long-term goal and a significant achievement for my personal growth.

It’s clear you have a real passion for the business and what you do. Is it true you know every item of equipment in the rental portfolio?

Yes, it’s true and I take great pride in knowing the ACE Winches offering and equipment portfolio inside and out. Of course, none of this would be possible without the wider ACE Winches team and our expert engineering team and technicians. Their skills in the design, engineering, manufacturing, and maintenance of our equipment are the backbone of our operations. The dedication they bring to their craft ensures that every piece of equipment we offer is of the highest quality and reliability.

I’m fully invested in our success. Our collective efforts are what make this business so dynamic and rewarding, and I am proud to be a part of it.

Richard Lind, General Manager for Ashtead Technology’s Mechanical Solutions Centre of Excellence in Thainstone, Aberdeenshire, to discuss this plans for continuous growth in its technology, capabilities and people.

Richard, Ashtead Technology’s Mechanical Solutions Centre of Excellence has been making significant strides. Can you tell us about the growth of your team?

Absolutely! Over the past year, our team has grown a significant amount. We’ve been actively recruiting talented individuals who bring diverse perspectives and fresh ideas to the table. As we continue to expand on our technology portfolio, we aim to continue the recruitment drive with trainee mechanical technicians. Our focus is on building a team that is not only technically proficient but also highly collaborative, ensuring that we are always at the forefront of industry developments.

What cutting-edge technologies can trainee technicians expect to work with at Ashtead Technology?

At Ashtead Technology, we lead in technological innovation, designing equipment based on customer needs. Our latest creations include the patent-pending 23” Ring Saw, offering double the cut depth at half the size of conventional saws, and the Mattress Recovery Tool (MRT), a cost-effective solution for recovering subsea mattresses. As a trainee technician, you’ll receive comprehensive training to operate and maintain these advanced systems, preparing you for a successful career.

How does Ashtead Technology envision the growth of its Mechanical Solutions centre of excellence?

At Ashtead Technology, our growth focuses on three key pillars: technological advancement, capability expansion, and people development. By investing in the latest technologies and nurturing our talent through ongoing training, we enhance our services and explore new areas for expertise.

Our investments are yielding significant results, positioning us to tackle future challenges and seize new opportunities. We are committed to pushing the boundaries of what’s possible, ensuring we remain leaders in the mechanical solutions industry.

What opportunities does Ashtead Technology offer for aspiring Mechanical Technicians?

Ashtead Technology is dedicated to excellence and innovation. As a mechanical trainee technician, you’ll join a dynamic environment where collaboration and cutting-edge projects thrive. We offer structured training and mentorship to support your professional development and help you push the boundaries of mechanical solutions.

If you’re ready to take your career to the next level in mechanical engineering, Ashtead Technology is the place to be.

How can interested candidates apply to join your team?

If you’re excited about the prospect of joining our team and contributing to our growth story, we encourage you to apply online through our careers portal. We’re looking for motivated individuals who are eager to learn and grow with us. Take the first step towards a rewarding career at Ashtead Technology and join us in shaping the future of mechanical solutions.

The offshore energy industry is constantly evolving, and in 2024, remote operations are increasingly important. Ashtead Technology is proud to offer this service that not only enhances safety and agility but also promotes sustainability.

What are remote operations?

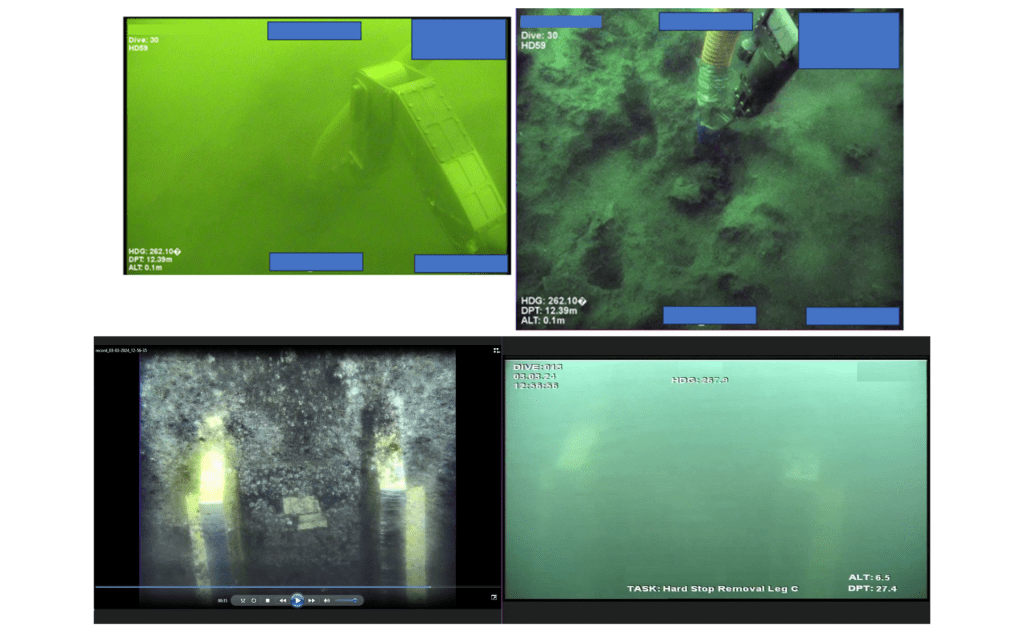

Remote operations involve performing offshore tasks from onshore locations. This can include using advanced technologies, like underwater robots and real-time data analysis to inspect equipment, monitor well integrity, and even perform maintenance.

Ashtead Technology is a leader in remote operations, supporting our customers safely, flexibly and sustainably.

This rise of remote operations

Traditionally, the offshore energy sector has been characterized by complex, resource-intensive operations with inherent safety hazards. However, the industry’s focus on sustainability and cost-efficiency has led to the exploration of remote operations as a solution. Remote operations involve the use of unstaffed or minimally staffed vessels or platforms to conduct a wide range of offshore tasks, including inspections, maintenance, drilling and production.

The digital revolution has significantly impacted offshore operations, fostering the adoption of advanced remote technologies like unmanned surface vessels (USVs), remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs). These technologies have revolutionised the industry by reducing travel costs, bolstering safety and efficiency, and paving the way for a more sustainable and resilient future of offshore energy.

Why join the revolution?

- Safety: By reducing the number of personnel required offshore, remote operations can significantly decrease the risk of accidents and injuries

- Cost-effectiveness: Remote operations eliminate the costs of mobilising personnel, making projects more economical

- Sustainability: Remote operations help reduce emissions by minimising the required size of vessels and reducing personnel transits (air travel, helicopters vessel port calls), promoting environmental responsibility

- Efficiency: Remote operations centres allow specialists to collaborate seamlessly, regardless of location, leading to fast project completion.

Ashtead Technology’s Remote Operations expertise

Ashtead Technology boasts a proven track record in remote operations, with dedicated remote operations centres in the UK and Canada. Our Asset Integrity team utilise technologies like machine vision measurement systems and 3D imaging technology for remote inspections, ensuring the highest quality standards.

We have successfully delivered remote inspection projects around the globe, including the North Sea, West Africa, Australia, Brazil, Southeast Asia and the USA. Our remote operations solutions offer our customers flexibility and reliability. This is achieved by allowing inspection vessels to remain on-site and conduct additional work scopes eliminating unnecessary port returns

Our remote operations teams can be mobilised within 48 hours, provide continuous 24/7 coverage, and immediately stand down upon project competition. We also provide hybrid remote operations, combining the flexibility of remote service with on-site technical support through a model where one offshore operator collaborates with a back-to-back onshore remote operator, each working 12 hours.

The future of Remote Operations

As technology continues to advance, we can expect remote operations to become even more established. Ashtead Technology is well-positioned to be a leader in this field, offering customers the tools and expertise they need to succeed in today’s competitive environment.

What motivated you to pursue a career in engineering?

I have always been interested in electronics and engineering, so I decided to study this at college and see where it took me. Being one of few female students at Moray College Technical Campus was slightly daunting to begin with, especially after having a large group of female friends in high school. However, I settled in quickly, which made me even more determined to make my mark in the engineering world.

How has Ashtead Technology supported your career?

Since joining Ashtead Technology two years ago, my colleagues offshore as well as the office staff have been very supportive of me – both personally and professionally. The collaborative and supportive culture within the company has greatly contributed to my growth in my role, providing reassurance that I have a network of colleagues who are willing to offer their expertise and assistance whenever needed.

Could you tell us about a project you have particularly enjoyed working on during your time at Ashtead Technology?

My career was driven by a deep fascination with the subsea environment. The nature of the subsea industry and the complex challenges associated with its exploration and development ignited a strong interest within me. The energy sector’s dynamism and unwavering commitment to continuous innovation and progress make it a truly fascinating field. It is an industry that presents endless of opportunities for growth and positive impact, making it highly inspiring.

Could you tell us about a project you have particularly enjoyed working on during your time at Ashtead Technology?

My first project with Ashtead Technology was the NNG Offshore Wind Farm. During this project, I spent time on several vessels in the field and met some lovely people! The project came with its challenges, which allowed me to further my knowledge of Ashtead Technology systems and gain valuable experience liaising with clients and other working parties onboard the vessels.

While on the project I was working as part of a 3-person survey team, operating and maintaining the SCT (Sonar Calliper Tool) and UCS Dredge tool. After another vessel had drilled into the seabed and installed the casings, we could deploy the SCT to carry out scans in the socket. Once all the information had been gathered, a report would be complied by the Ashtead Technology team and issued to the client onboard.

In your opinion, what are some key initiatives or strategies that can help encourage more women to enter the engineering field?

I believe that an early exposure to STEM is important. Engaging with STEM subjects from a young age can build confidence in girls, making them more likely to pursue further education and careers in these areas. Normalising women in engineering is equally important. Some girls may be scared to break the mould and come away from the ‘stereotypical’ female careers due to lack of role models and support. I’m passionate about encouraging more women to pursue careers in engineering – I always enjoy talking to young females interested in pursuing a career in a ‘male dominated environment’.

What advice would you give to females looking to get into engineering?

Don’t be afraid to ask questions and explore all your career options! Engineers are required in almost every industry, not just offshore. By keeping an open mind and investigating various fields, you can find a career path that truly aligns with your interests and skills.

Ashtead Technology is proud to offer our customers across the globe i2S’s advanced camera solutions. Through our strategic partnership with i2S, a leading manufacturer of innovative underwater camera systems we are their exclusive global rental and resale partner, providing our customers with unparalleled access to i2S’s industry-leading technology, including OrphieScaph and OrphieCam.

As the leading experts in subsea technology, we are keen to provide solutions which helps our customers see more in the harsh and challenging subsea world. Through this partnership our customers have access to i2S’s latest addition, the OrphieScaph, a compact camera delivering superior performance in low-visibility environments.

Phil Middleton, Head of Survey and Robotics commented : “Our collaboration with i2s strengthens our commitment to providing customers with the most advanced and reliable equipment for their subsea operations. The i2s camera range perfectly complements our existing offerings, allowing us to deliver exceptional visual data acquisition capabilities for a range of underwater projects.”

By using i2S cameras for their operations, our customers can achieve significant advantages. The exceptional low-light performance of these cameras allows us for extended working hours and efficient task completion in challenging underwater environments. i2S cameras deliver crisp, high-resolution images, facilitating meticulous data collection and informed decision-making. The superior reliability and durability of these cameras minimize downtime and ensure project continuity.

We’re committed to providing our customers with the most advanced and reliable equipment solutions for their subsea operations. This partnership adds to Ashtead Technology’s portfolio of more than 23,000 technology solutions, enhancing the company’s position as a leading provider of subsea technology.

For any questions or to learn more about how Ashtead Technology can assist with your project needs, get in touch with one of our experts.

Learn more about the OrphieCam

Learn more about the OrphieScaph

Rob joined Ashtead Technology as an Onshore Survey Technician, later advancing to the role of Senior Onshore Survey Technician. Rob supports the Survey & Robotics Team through updating procedures, testing equipment, and offering internal workshop assistance when needed.

Tell us about your role here at Ashtead Technology

I joined the Survey & Robotics team 10 years ago, serving as an Onshore Survey Techician. Over the years, my role has evolved, which has led to working in several departments across the group, allowing for a well-rounded view of operations within the workshop.

My current responsibilities as a Senior Onshore Survey Technician include updating procedures for testing equipment, alongside providing internal support to the workshop where needed. Additionally, the workshop manager will assign me tasks to implement changes or improvements, to allow the workshop to run more efficiently.

What did you study at college and what interested you in this field?

After finishing my NC, I pursued my HNC/HND in Electronic Engineering at NESCol. My interest in this field was sparked by my studies in Physics and Technical Studies during school. Progressing to Electronics at NESCol allowed me to further this interest.

It also became quickly apparent that having a qualification in Electronic / Electrical or Mechanical was, and continues to be, a sought-after skill set within Aberdeen – allowing for various opportunities as my experience has developed.

What have been the positives to starting your career on a Trainee programme?

Being a trainee offers numerous advantages. It provides a valuable opportunity to apply theoretical knowledge in practical setting from more experienced members of staff and benefitting from mentorship throughout the process.

What do you enjoy about working in the Survey & Robotics Team at Ashtead Technology?

There are several different departments within the workshop, each requiring a different approach, meaning there is always something exciting happening.

I find running repairs particularly enjoyable as it requires a deeper understanding of how the equipment works and an aptitude for troubleshooting. There is always something new to learn, even with equipment that has undergone numerous repairs. This has been true for me through updating the procedures, as it entails research to ensure the accuracy and currency of information provided.

Can you share a piece of work you were part of that was a highlight of your career?

Updating the in-house procedures has been something that has been especially rewarding. It has allowed me to further my knowledge whilst also continuing to improve our already solid foundation, helping new and experienced technicians.

The difference it has made is already notable, and the team are enthusiastic when proposing improvements for the equipment they specialise in. This enables us to uphold and enhance the high standards expected by our clients.

What piece of advice would you give Trainee’s in their first role?

With a strong work ethic and a readiness to learn, this role offers an excellent opportunity to start your career. With a solid internal support system in place, there’s always an opportunity for continuous learning and growth at Ashtead Technology.

Matthew Brown joined Ashtead Technology as a Workshop Technician, before being promoted to Senior Workshop Technician last year. Matthew works alongside other Senior Workshop Technicians to ensure the smooth running of the workshop, and providing technical support to our clients. He is also involved in the development of new products and services.

We asked Matthew to reflect on his time with Ashtead Technology and to offer insights and advice to trainees embarking on their careers in the subsea technology industry.

What did you study at college and what interested you in this field?

Originally, I wanted to study physics at university, but like to many, I didn’t get the grades I needed. Instead, I saw it as a chance to change direction and went to college to study Electronics.

I chose Electronics because it offers many opportunities for future careers. There are various paths you can take once you have the qualification.

What have been the positives to starting your career on a Trainee programme?

You receive hands-on training directly from industry experts, enabling you to apply theoretical knowledge under the mentorship of experienced team members. A clear career progression path is laid out for you, based on achieving competency targets, allowing you to continuously enhance your skill set and provide advancements in your career. Plus, you can earn income while gaining invaluable knowledge and skills.

What do you enjoy about working in the Survey & Robotics team at Ashtead Technology?

Working with my colleagues at Ashtead Technology is fantastic; we foster a culture of support and collaboration, ensuring that our deliverables meet high standards. Each of us is driven to excel in our roles. We work with the latest technology in the industry, keeping us ahead of the curve in terms of skillet and technological knowledge.

The dynamic nature of our work ensures that each day brings new challenges and opportunities. Personally, I’ve had the chance to travel to Holland, while our team members have travelled to Singapore, Dubai and Houston to support our teams across the world. The role provides ample opportunities to travel and explore different parts of the world!

Can you share a piece of work you were part of that was a highlight in your career?

A highlight for me was the trio to Ijmuiden, Holland last year to assist one our clients. We successfully implemented a modification on a subsea multiplexer, enabling our client to seamlessly transition to the next phase of their survey project with minimal downtime. It was great achievement and a positive outcome for all involved.

What piece of advice would you give Trainee’s in their first role?

For trainees starting their first role, I would emphasize the importance of being proactive and open-minded. Take imitative to learn as much as you can about your role, the company and the industry. Don’t hesitate to ask questions and seek guidance from colleagues. Embrace challenges as opportunities for growth, and maintain a positive attitude even during the inevitable setbacks. Finally, remember that building strong relationships with your team and demonstrating reliability and professionalism are key factors in your success.

Interested in a traineeship with Ashtead Technology?

Rachel Buchan joined Ashtead Technology last year as a marketing intern. With her innovative ideas and unwavering enthusiasm, Rachel has quickly become an integral part of our team.

We asked Rachel to reflect on her time with Ashtead Technology so far.

Tell us about your internship at Ashtead Technology, so far?

I started my year-long internship within the marketing department in May last year. During my internship, I have been supporting the team with event planning, brand management, corporate communications and global marketing.

Ashtead Technology pride themselves on their market leadership and level of expertise within the business. The depth of knowledge and enthusiasm displayed by my colleagues on a daily basis never fails to impress me. With a strong focus on people, Ashtead Technology fosters a supportive environment where everyone is eager to lend a hand and take the time to provide guidance and explanations, which has been particularly beneficial during my internship.

What inspired you to do an internship?

As part of my undergraduate degree, we are encouraged to carry out a year-long internship to gain valuable work place experience. I believe that experience in the field plays a crucial role in establishing a pathway for post-academic ventures. In terms of marketing, my sister was my inspiration as she is constantly enthused by her role in marketing. The energy industry holds a special significance in my family with my Dad working in the industry for around forty years. His worth ethic, expertise and enthusiasm have always inspired me. While looking into internships, he reminded me how many opportunities and room for progression there is in the industry, so it was really a no brainer.

What have you learned so far from your internship?

Throughout the course of my internship, I’ve developed a range of technical skills in marketing, covering digital marketing, event planning, content creation, and brand management. In addition to these technical skills, my newness to the energy industry has fuelled a continuous expansion of my knowledge in this sector. Lastly, I’ve gained various personal skills during my placement – there’s a noticeable improvement in my confidence, adaptability, and communication since the start of my internship.

What have you enjoyed about your internship so far?

I would say the best part of my internship so far has been contributing to event planning, as it provides an outlet for my creative skills. Observing an event’s journey from the planning stage to its execution is really fulfilling. Shortly after joining, I became a part of the social committee, where I actively participate in event planning for employee social events and charitable initiatives. The committee provides a fantastic opportunity for me to merge into the company culture and share my ideas. I have also enjoyed connecting with individuals at industry events, thanks to the social aspect of my role.

What do you hope to achieve in your time here?

I aspire to continuously broaden my understanding of marketing initiatives and contribute to the success of the marketing team, whilst deepening my familiarity with the energy sector. I aim to acquire enough experience to confidently secure a job after my graduation from university next May.

What advice would you give to anyone considering an internship?

I highly recommend pursuing an internship to anyone. The experience you gain is invaluable – it not only provides insights into your future career, but also develops personal skills, including confidence, teamwork, and independence. My advice to anyone starting an internship is to actively engage by joining committees, interacting with colleagues, attend industry events, and be proactive.

Phil Middleton Ashtead Technology’s Head of Survey & Robotics joined the company in May 2022 to further strengthen existing capability across Ashtead Technology’s core markets and drive forward our ambitious growth strategy. Here, he discusses his thoughts since joining the company and how through continued investment in our survey & robotics rental fleet and our people, we remain at the forefront of what we do to support our customers globally.

Now six months in to the role, discuss your time with Ashtead Technology so far.

Having worked in the subsea technology sector for many years now, I have always been aware of the expertise within Ashtead Technology and the extensive availability of quality equipment the company has to offer customers. Now as an employee, I have been blown away by the breadth and depth of capability throughout the business and the company’s unwavering commitment to quality and service excellence, which is interwoven into everything the company does, and stands for.

Ashtead Technology is on an ambitious growth journey and it is great to be part of a business that has the expertise, talent, resources and buying power to lead the way in the sector and make a real difference to our customers.

What are the biggest challenges in the market and how is Ashtead Technology addressing these?

In all the customer conversations I’ve had, the main challenges are equipment shortages, the lack of competent and skilled personnel and supply chain constraints which all have the potential to negatively affect the timely, safe and efficient delivery of our customers ‘projects.

Ashtead Technology is addressing the equipment availability shortages through ongoing investment in our subsea equipment rental fleet which has in excess of 17,000 assets. Early engagement with both customers and our suppliers is key to ensuring we have visibility of their short, medium, and longer-term requirements enabling us to plan ahead and secure the availability of equipment.

We also take a proactive approach to training our people so we have a highly competent and available workforce to support the mobilisation of mission critical equipment. Mentorship and on-the-job training are fundamental to the career development journey of our employees. This ensures that essential expertise is nurtured within the business and passed on to the next generation of talent enabling them to excel and thrive in a fast-growing environment and deliver for our customers. Should we feel there is a competency gap, we provide our employees with practical training from the OEM so our global pool of technicians have an expert understanding of our entire fleet of subsea equipment.

This commitment to technical excellence is also evidenced by our local community involvement in STEM (science, technology, engineering and maths) initiatives, where are broad knowledge and expertise is shared with local schools, colleges and universities.

Furthermore we provide equipment awareness training to our key customers which provides a high level understanding of our equipment, ensuring mobilisations and offshore operations run smoothly.

What’s next for Ashtead Technology in the survey and robotics field?

As a progressive and pioneering business, we continually aim to offer the broadest and most technologically advanced subsea equipment from leading manufacturers.

Ongoing investment is essential, and we have committed to further capital expenditure for 2023 and beyond to ensure that our portfolio of technologies continues to meet our customers‘ current and future operational challenges.