Enhanced chain measurement using Ashtead Technology’s optical CMS

Overview

Ashtead Technology’s customer, an international energy company, required a mooring chain measurement solution for their asset, a North Atlantic FPSO, that could provide accurate and repeatable mooring chain measurements for tracking chain corrosion and wear between surveys.

The North Atlantic is one of the most challenging environments in which to maintain mooring integrity for floating production systems, due to frequent storms and high fatigue loads year round, and the solution provided would need to operate effectively in harsh environments, where ROV operation was still possible.

Ashtead Technology performed this scope as part of a 10-year contract to provide asset integrity inspection services for our customer, along with riser and mooring rope cleaning and inspection, and underwater 3D imaging solutions.

Solution

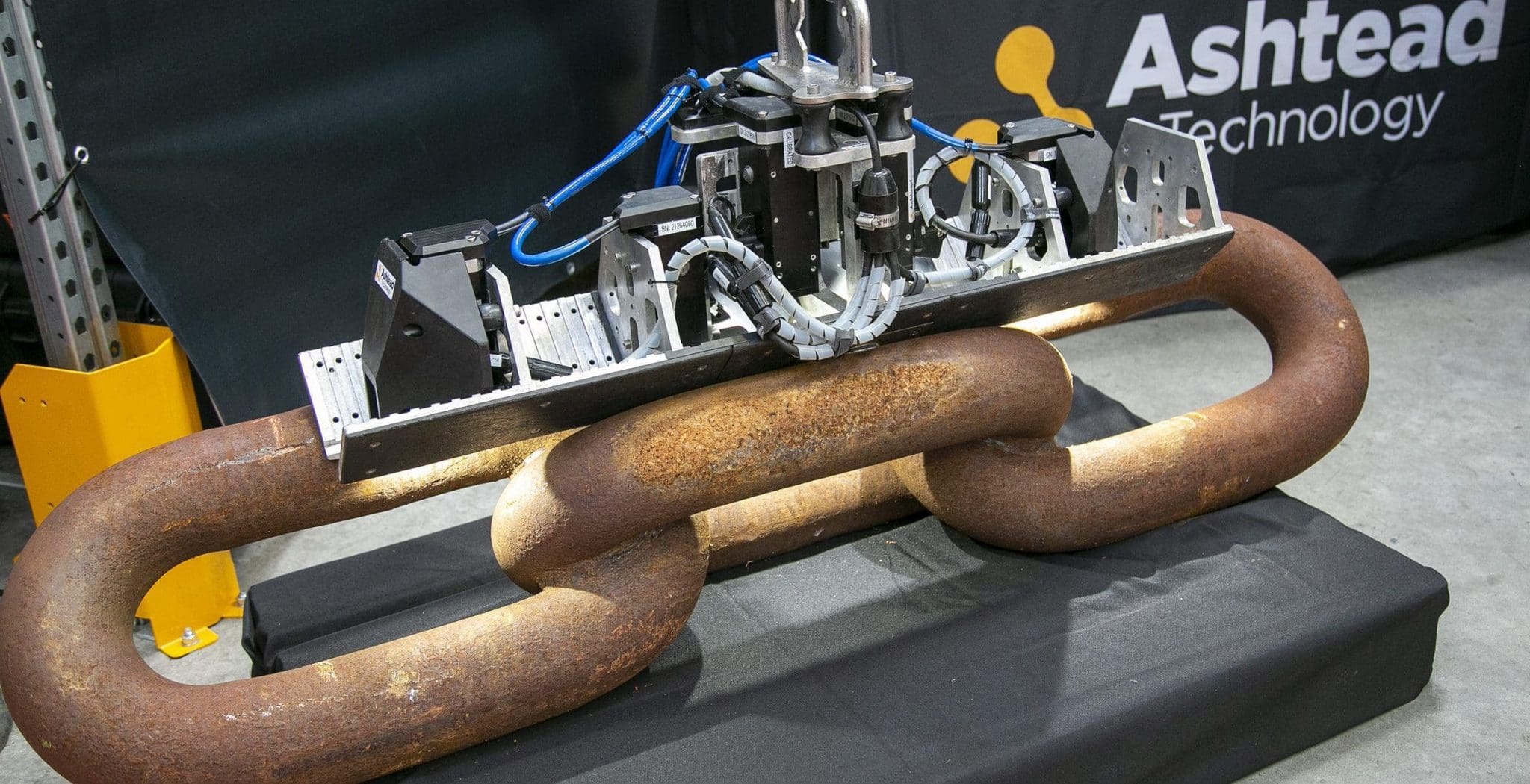

Ashtead Technology provided its state-of-the-art optical CMS as a turnkey solution to meet all the customer’s requirements.

Ashtead Technology’s optical CMS allowed all relevant chain dimensions including intergrip length, bar diameter, and overall link length to be measured simultaneously, eliminating the need for the ROV to come to surface for tooling adjustments between measurements. The optical CMS technology can also measure chain inclination to ensure sufficient pre-tension and load sharing between lines.

Chain measurement operations took place in November 2021 under marginal weather conditions for ROV operations.

Benefits and value

Ashtead Technology’s optical CMS was able to reduce chain measurement time by more than 50%, helping to reduce ROV/vessel operational time and cost, compared with other chain measurement technologies, such as mechanical calipers, photogrammetry, or laser measurement systems.

Using a combination of high-resolution video and machine vision algorithms, the optical CMS was able to provide accurate measurements of chain dimensions within seconds of tool placement and deliver real-time results for our customer.

Mooring chains are designed with corrosion and wear allowances to ensure they meet minimum safety factors for fatigue and breaking strength and measuring chain deterioration is an accepted performance standard to provide assurance throughout life of field. Ashtead Technology’s extensive experience in this space, combined with our knowledge of how mooring chains deteriorate and eventually fail, enables us to develop advanced technologies and inspection solutions that are helping to deliver optimal efficiency for our customers worldwide.

Ashtead Technology is a market leader in mooring system inspection having completed over 200 projects worldwide. With a strong culture for innovation and continuous improvement, our asset integrity team has developed a new state-of-the-art optical chain measurement system (CMS) that provides highly accurate and repeatable mooring chain measurements to track chain corrosion, wear and elongation between surveys.

Ashtead Technology’s new optical CMS technology is proven to be the most accurate and reliable chain measurement solution for the global offshore energy sector, including in regions where there is high mooring chain motion.