Intelligent positioning, telemetry and shallow water

Overview

Ashtead Technology’s positioning, telemetry and shallow water trenching spreads delivered leading-edge technical data and rapid project completion. With increasingly high volumes of data and power requirements carried by subsea cables, it is imperative that they are routed and secured correctly for maximum durability and performance.

Ashtead Technology was approached by a cables, energy and telecoms solutions provider for its first-ever collaborative project. This offshore project in American waters required a surface interconnect cable-lay. The cable was to be surface-laid and then trenched using a shallow water jet trenching ROV. Ashtead Technology was chosen thanks to its considerable experience to date in assembling specialist survey spreads, which rapidly unlock reliable, decision-influencing data.

Solution

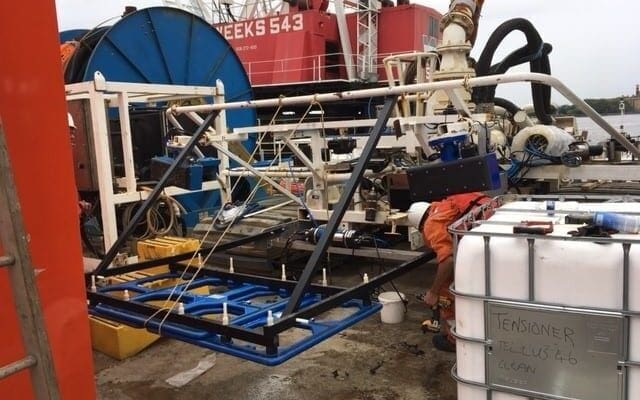

The initial phase of the project saw a bespoke positioning and telemetry spread compiled by Ashtead Technology mobilised from a cable-laying vessel. Incorporating subsea positioning and touch down monitoring, this solution was tailored to the client’s exact specification by Ashtead Technology’s Survey & Robotics specialists, delivering actionable and accurate positioning by way of an Octans FOG, Satel radio modem, ADCP and intelligent pressure sensors.

The second phase required a robust shallow water trenching spread to acquire accurate bathymetric data for an as-left survey. This spread used a broad array of solutions selected for both reliability and performance by our specialist team, including a Kongsberg Hi-Pap 350P, MBES, Octans FOG, Gemini 720i all interfaced through an Innova Matrix.

Benefits and value

Ashtead Technology’s international reach enabled considerable cost savings to be realised for the client, with this project-specific solution mobilised at our UK facility. Project shipping costs were also minimised thanks to the use of Ashtead Technology’s regional offices and our network of logistics experts worldwide.

Full redundancy was engineered into the project from the start, enabling maximum project uptime with a full complement of spares onboard. This enabled the project to be completed within 150 days, ensuring the client met their timescales and onward obligations.

Testimonial

“Ashtead Technology’s international team of survey technician personnel were on hand to assist with a seamless mobilisation process, assisting with equipment deployment, technical advice and streamlining turnaround times where required.”

“Ashtead Technology are delighted to have been of service to the client during its first-ever scope for them and aim to continue this relationship with bespoke survey and robotics solutions in future.”