Engineering the future – by Ross MacLeod

15 August 2023

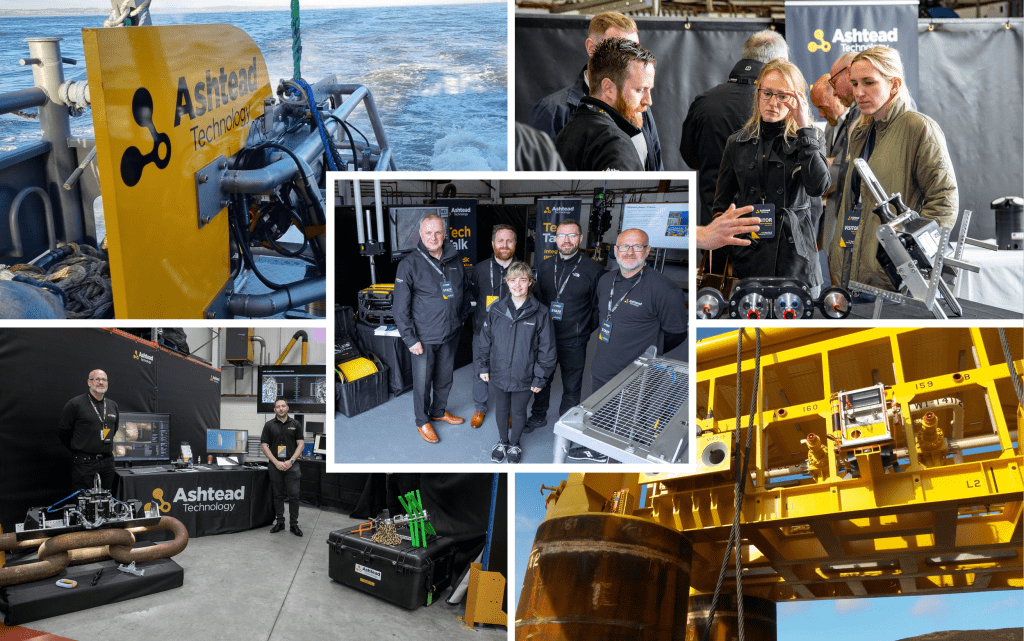

Underpinned by our deep heritage, knowledge and extensive experience in the subsea and robotics sector, Ashtead Technology has built an established track record in the delivery of custom engineered solutions for the offshore energy sector. Our ability to understand what and where the challenges are and how these can be overcome has resulted in the pioneering development of several new technology innovations particularly in the asset integrity space.

Spearheading our technology development programme is Ross MacLeod, Ashtead Technology’s Integrated Projects Director. Ross joined Ashtead Technology in 2011 as Business Development Director prior to taking on the role of Technical Director in 2017, where he played a significant part in growing our technical services offering and in-house engineering capability across our survey & robotics and asset integrity service lines. Ross became Ashtead Technology’s Integrated Projects Director in 2022 to support the successful delivery of increasingly larger engineering work scopes as our customers’ trusted subsea technology partner.

He added: “Core to developing the optimum solution is listening to the customer and understanding their unique challenge. As a subsea equipment rental business with 38 years’ experience across the sector, we have first-hand experience of what will and won’t work – we have seen it all. Ultimately, we want to help our customers’ and we will always consider what will add most value, be more efficient, reduce operational risk and vessel time.”

Our evolution and early developments

It was some notable successes in the engineering space that led to an organic shift in our offering. No longer just a ‘box rental’ business, Ashtead Technology has evolved to become an integrated subsea technology and solutions partner – with our passion for solving problems, combined with our market-leading technology portfolio, we deliver innovation, operational excellence and specialist engineering services to support our customers’ projects.

The launch of Ashtead Technology’s Autonomous Monitoring System (AMS) in 2016 was the start of the development of a range of game-changing proprietary products for subsea inspection and monitoring applications. Based on feedback from customers, current systems had too many design limitations and were not multi-functional, so Ashtead Technology created a next generation configurable autonomous monitoring solution for measuring headings and pitch & roll using the latest technology, solid state fibre optic and ring laser gyros. Evolving from the AMS was the Deflection Monitoring System, a suite of structural monitoring systems to support offshore construction operations, combining powerful software with modular technology. The system monitors critical structural information, allowing real-time adjustments to be made during installation, ensuring the structure is set in place quickly and within installation tolerances.

Supporting the offshore renewables sector

Our growing track record in the development of offshore technology solutions has resulted in further pioneering work in the offshore wind sector and specifically for the installation and construction phase. Our reputation for being inventive, knowledgeable and responsive has created opportunities for us to develop custom engineered solutions for wind energy operators and service companies to support borehole inspection, borehole internal casing cleaning, grouted pile installation and grout level monitoring. Core to our recent success has been the acquisition of complementary companies which have further bolstered our mechanical solutions capabilities and in-house engineering expertise to help develop truly unique solutions for customers.

Ross said: “The acquisition of Undercutting Cutting Solutions in 2019 came at the perfect time for our business as we were able to leverage their strong capabilities to support various work scopes for the Neart na Gaoithe offshore wind farm which we were awarded in 2021. Specifically, their offshore cleaning and dredging technology know-how was used to develop custom solutions for preparing the socket bases before grouting could commence as part of the foundations installation phase.”

Development of proprietary products

By being able to design and build our own custom equipment, Ashtead Technology is not constrained by the availability of existing equipment in the market and can focus on developing the right solution for our customers’ project needs. A key strength is our ability to design integrated electrical systems, instrumentation, telemetry and hydraulic control systems which offer sophisticated functions and safety features whilst remaining robust and reliable for operation in the marine environment.

Recent developments have included our ROV/ Diver deployed Cathodic Protection (CP) Measurement System for robust subsea CP monitoring; our Chain Measurement System, a ROV-deployed optical caliper imaging device; and our new standard Drop Camera System, part of a range of systems designed for high-resolution seabed visual inspection, in water depths up to 4000m.

Ross added: “We are at an exciting stage in the evolution of our business with some very interesting projects in the pipeline. Investment in the business through growing our team, expanding our product and service offering and acquiring highly complementary businesses has truly strengthened our company and positioned Ashtead Technology as a go-to-partner for service and engineering excellence with a robust suite of products and services, that we can be proud of.”